About Gasflux

The Process

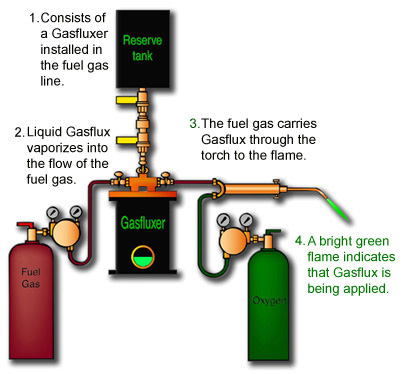

The Gasflux® Company Process introduces a flux automatically into the flame for manual or automatic torch brazing applications. Introduced into the fuel gas, Gasflux® creates superior wetting action and encourages filler metal to evenly flow into the joint where it is needed most.

Used with bronze, silver, and copper-silver-phosphorus filler metals, Gasflux® produces joints of optimum strength and outstanding appearance while reducing post-braze

cleanup costs.

The result is increased productivity with reduced material and application cost!

Used with Filler Metals:

| AWS Spec 5.8 | Description |

|---|---|

| RBCuZn | Bronze & Nickel Silver |

| BCuP | Copper / Silver / Phosphorus |

| BAg | High % Silver & Flux-Cored Silver |

Used with Base Metals:

| Base Metals |

|---|

| • Copper • Brass • Carbide • Steel • Stainless Steel |

Applications in the Field

- Air conditioning and refrigeration

- Automotive components and tubular assembly

- Bicycles

- Commercial Filters

- Compressors

- Copper Busbar

- Dental Equipment

- Drilling Equipment – Mills, Blades, Stabilizers, and Rotary Shoes

- Flexible Metal Hose

- Hospital Equipment-Wheelchairs & Patient Aids

- Jewelry - Gold and Silver

- Metal Art Forms & Sculptures

- Metal Furniture

- Plumbing Assemblies - Copper & Brass

- Valves - Brass

- Steel Windows and Doors

- Any silver or bronze brazed assembly using brass, copper or steel as the base metal